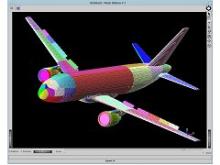

AIRBUS Group - Aseris Project

Client:

AIRBUS Group

Skills:

Modeling, Visualization, Data Exchange, Graphical Interface

Categories:

Provide pre and post processing for ASERIS Electromagnetic Compatibility code.

Mission

- Provide pre and post processing for ASERIS Electromagnetic Compatibility code.

Solution

- Open CASCADE Technology components and proprietary 3D-Master Suite graphic interface components were used to create the Integration chain that now enables ASERIS-FD to pre and postprocess simulations on an imported CAD model.

- Open CASCADE Technology allows importing CAD model data from different types of modeling software into the application through standard formats such as IGES and STEP. Next, the model data is meshed and exported along with material data to an external solver.

- OPEN CASCADE developers have worked on ASERIS-HF (high-frequency method) and ASERIS-NET, two other electromagnetic simulation applications used by EADS. ASERIS-FD simulates effects on materials and does not need to take into account the overall topology of the CAD model, whereas ASERIS-HF uses information concerning the electromagnetic nature of the model and requires complete topology.

- To meet this challenge, the development team implemented an iterative sewing function that displays the topology as it is progressively joined. In this way, the user is able to check whether results are correct and, if necessary, change the parameters from one step to another.

Benefits

- user interactivity

- faster preparation of models for simulation

- productivity gain