Arcelor - ISOPUNCH

Client:

Arcelor

Skills:

Architecture, Ergonomics, Pre & Post-processing, Solver Integration

Categories:

Design offices to predict stamping problems early in the design cycle.

Mission

- The Arcelor group develops its activities in 4 core businesses : it is the world's biggest producer of Flat Carbon Steel and Long Carbon Steel, one of the leaders in Stainless Steel production, and among the largest firms in Europe for Distribution, Transformation and Trading.

Solution

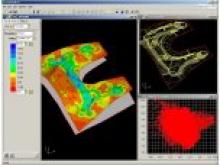

- To assist its customers, Arcelor distributes a specific ISOPUNCH software application which helps analyze stamping results for parts made from the flat steel sheets produced by Arcelor.

- This application is used by design offices to predict stamping problems early in the design cycle. These can be wrinkles, tears, surface aspect irregularities or other deformations.

- Since its creation, ISOPUNCH has been continually enriched. Because of the growing multiplicity of functions, on the one hand, and of evolutionary needs, on the other, it was necessary to reengineer the architecture and ergonomics of the application. To do this, Arcelor called on OPEN CASCADE.

- In a first analysis phase, we designed the new architecture and ergonomics of ISOPUNCH from Arcelor vision.

- In the second phase, we developed the pre- and post-processor based on this new architecture and ergonomics, the existing mesher and solver developed by Arcelor being plugged in this new application infrastructure.

Benefits

- Ease the work of analysts, thanks to the integrated user interface providing direct access to the geometry of the part, the mesh and result of calculation from a single user-friendly environment

- Data input set on the geometry of the final stamped part instead of the mesh

- Portability of the pre- and post-processor

- Running in an heterogeneous distributed environment : pre- and post-processor on Microsoft Windows and mesher and solver on SGI Irix