Asset Revamping

Visualize, Simulate and Operate an Industrial Asset

Helping heavy industries to adopt to rapid digital transformation, Open Cascade developed a state-of-the-art software solution Asset Revamping. It is one-of-a-kind client-server web application providing quick access to realistic, interactive and easy-to-use 3D hybrid data for unlimited number of stakeholders across worldwide locations. Asset Revamping is a fully-fledged collaborative tool allowing not only viewing huge assets of massive 3D data while working iteratively, but also commenting, filtering, highlighting critical areas in a scene, taking measurements, simulating different scenarios, etc.

Asset Revamping is the best solution for geographically dispersed teams when people from different locations need to quickly access industrial projects for day-to-day operations: design review, preparation of maintenance jobs or security team interventions, quality control, etc.

Experience high-speed streaming of huge 3D datasets and perform virtual walk throughout industrial facilities with maximum closeness to reality.

Asset Revamping configuration:

Self-hosted or vendor-hosted solution providing access to projects via a web browser on a PC or a tablet. 3 types of users are available:

- “Administrator” - a person who manages other users accounts

- “User” - somebody who has full access to projects and collaborate on them

- “Guest” – one who has read-only permission on projects

Feature-set:

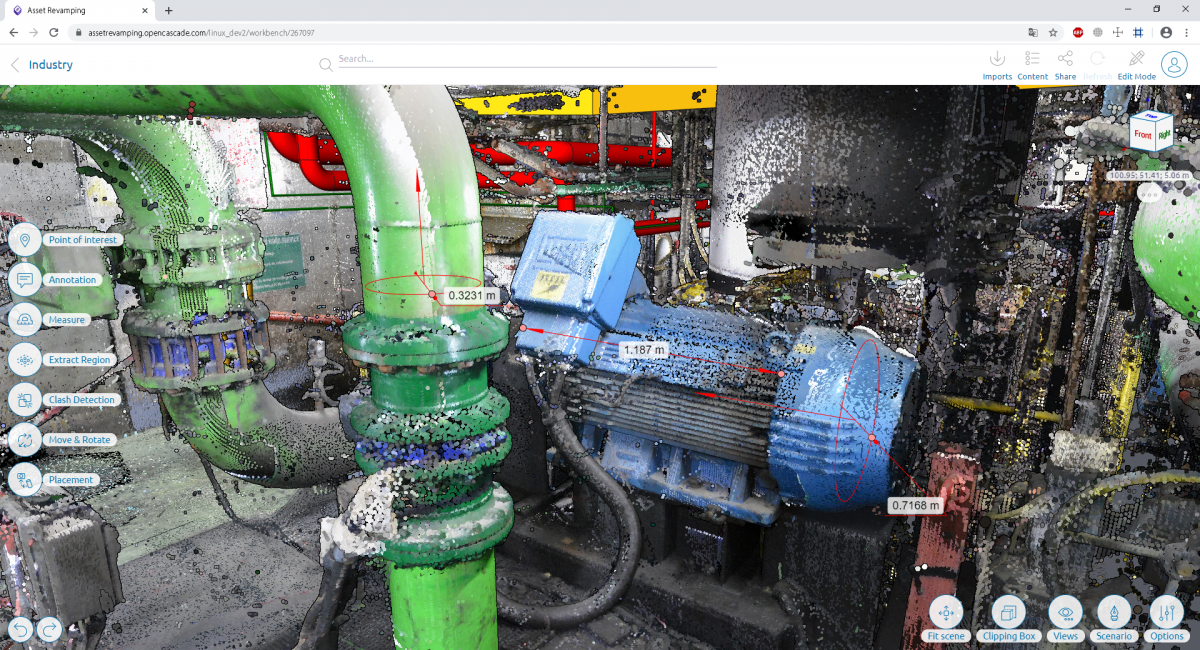

Review mode: Asset Revamping allows navigating through large-scale scenes coming from heterogeneous 3D sources (CAD and Point Cloud models can be viewed separately or interact in one scene). The good quality and high-level detailed environment resulted from laser scanning (point cloud) imitates a user’s presence on site providing a unique opportunity to remotely inspect industrial objects (plants, factories, models of planes, ships, cars) in each and every detail.

Editing features:

- Annotation attachment – for collaborative tasks annotations can be added to specific areas or objects (text, file, color assignment, copying to clipboard).

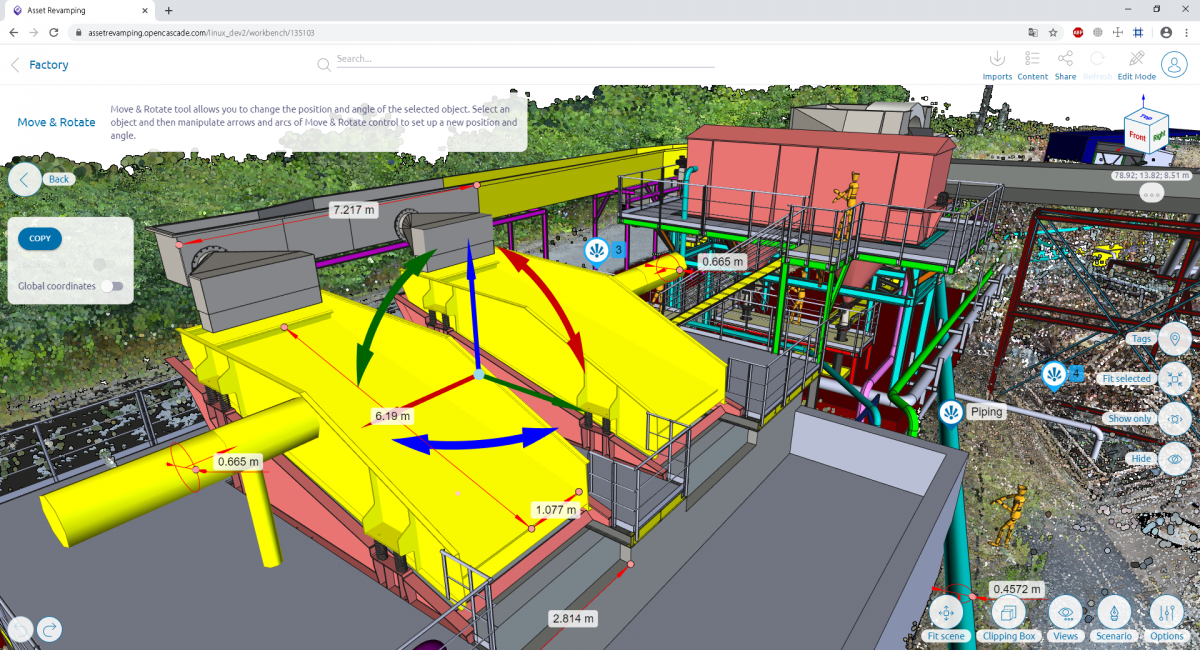

- Taking measurements – a user can measure the distance between two points and provide the related information in terms of XYZ projection.

- Region – capability for a user to isolate a part of a point cloud and to manipulate it as any other object.

- POI (Point of Interest) – a POI is associated to a specific point in the 3D space (generally related to an object or area which need to be highlighted) and can be extended by multiple attributes (e.g. text, video, file, etc.). It can be used as an annotating or commenting tool. Predefined POI of type “Scanning position” allows viewing 360° images taken by scanners’ cameras to make the navigation even more realistic.

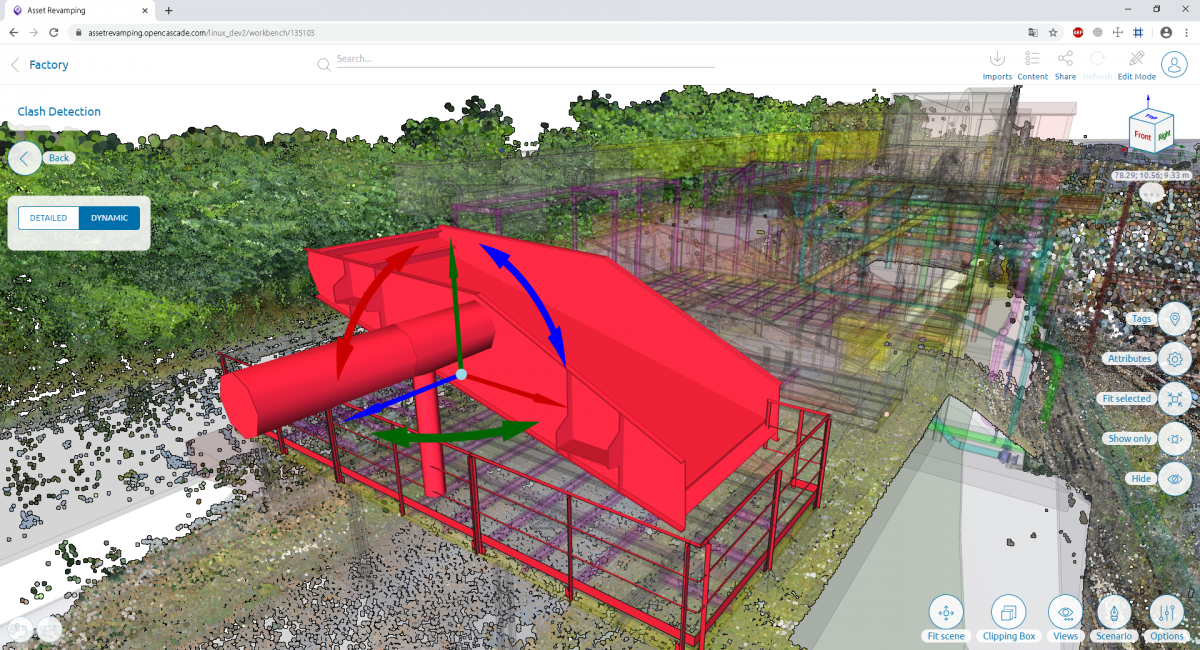

- Collision detection – the software allows dynamic detection of collisions between a 3D object and another 3D object or a point cloud. It is very useful to prepare and validate the feasibility of maintenance operations.

- Alignment – allows performing constraint-based object placement.

- Displacement of any objects – possibility to move objects within the scene, find optimized trajectories when combined with the collision detection feature.

- Preparation, playing and sharing of user scenarios – having access to realistic point cloud model of an industrial asset, a user can remotely simulate maintenance jobs, modifications (disassembly, minor revamping, dismantling), trainings, etc.

- Advanced search and filter by attributes – quick access to specific task-related objects and parts can be easily performed when filter or search are applied.

Key benefits:

- Web-based architecture - flexible access to industrial information by all stakeholders regardless their geographic locations via web browser leads to considerable costs savings on IT.

- One-place storage – large assets of industrial 3D data are aggregated in a single interface that eliminates the need for file exchange and leads to reduced error-rate, a time-efficient way to collaborate on projects.

- Hybrid 3D data processing – Asset Revamping effectively manages data from heterogeneous sources: CAD models and Point Clouds of almost unlimited sizes.

- Dynamic data loading – high-performance and high-speed of the solution is ensured by the fact that projects are not fully loaded at once and therefore high processing memory is not required: the data is loaded gradually according to users’ movement throughout the scene.

Supported formats:

Included in the basic version:

- - Neutral CAD file formats: STEP, IGES, JT, BREP.

- - BIM file format: IFC.

- - Mesh formats: STL, PLY.

- - Point cloud formats: E57, PTX, PTS.

Optional supported file formats:

- - Native CAD file formats: Catia 4/5/6/3DExperience, NX, Pro-E/Creo, Inventor, SolidEdge, Solidworks, Rhino, DXF, DWG, Parasolid/Acis.

Supported web browsers:

- - Firefox, Chrome, Safari.

Partnership with an expert

Our parnership with Imag'Ing, a recognized expert in 3D laser scan and revamping, assures rapid implementation of best-in-class usage practices for our clients.

v.1.3, 2020-07-08

v.1.2, 2020-04-29

v.1.1, 2019-11-29

v.1.3, 2020-07-08

v.1.2, 2020-04-29

v.1.1, 2019-11-29